Ці задумваліся вы, наколькі цяжкія машыны, такія як экскаватары і бульдозеры, атрымліваюць сваю неверагодную сілу? Сакрэт часта заключаецца ў тым, што называецца восевым поршневым помпай. Але вось пытанне, якое галаваломкі многіх людзей: ці сапраўды восевыя поршневыя помпы ствараюць ціск?

Кароткі адказ - так - але не так, як вы можаце падумаць. Давайце пагрузімся ў гэты займальны свет гідраўлічнай сілы і даведаемся, як працуюць гэтыя дзіўныя машыны.

Што менавіта ўяўляе сабой восевы поршневы помпа?

Падумайце пра восевы поршневы помпа як пра сэрца гідраўлічнай сістэмы. Гэтак жа, як ваша сэрца перапампоўвае кроў праз ваша цела, гэты помпа перамяшчае гідраўлічную вадкасць праз машыны, каб прымусіць іх працаваць.

Назва "Восевы поршань" паходзіць з таго, як ён пабудаваны:

- Аксіальныазначае, што поршні рухаюцца туды -сюды па той жа лініі, што і галоўны вал

- Поршаньставіцца да невялікіх цыліндраў, якія выконваюць фактычныя помпавыя працы

Гэтыя помпы асаблівыя, таму што яны могуць справіцца з надзвычай высокім ціскам - часам да 6500 фунтаў на квадратны квадрат (фунты на квадратны цаля). Гэта ўсё роўна, што вага чатырох машын націскаў на кожны квадратны цаля!

Вялікае пытанне: ці сапраўды яны ствараюць ціск?

Вось дзе гэта становіцца цікавым. У інжынерыі ёсць агульная прымаўка: "Помпа стварае паток, а не ціск". Хоць гэта гучыць разумна, гэта толькі частка гісторыі.

Праўда:Восевыя поршневыя помпы ствараюць спачатку паток, а потым ціск адбываецца, калі гэты паток адпавядае супраціву.

Уявіце сабе, каб сціснуць садовы шланг, пакуль вада праходзіць праз яго. Помпа (ваш кран) стварае паток, але калі вы сціскаеце шланг (ствараючы супраціў), ціск нарошчваецца. Тое ж самае адбываецца і ў гідраўлічных сістэмах.

Як гэта працуе ў рэальным жыцці

Ён падштурхоўвае фіксаваную колькасць гідраўлічнага алею з кожным паваротам

Гэта можа быць вялікая нагрузка, закрыты клапан або трэнне ў сістэме

У вадкасці больш няма куды, таму ціск павялічваецца

Гэты ціск - гэта тое, што падымае цяжкія прадметы альбо рухаецца машынамі

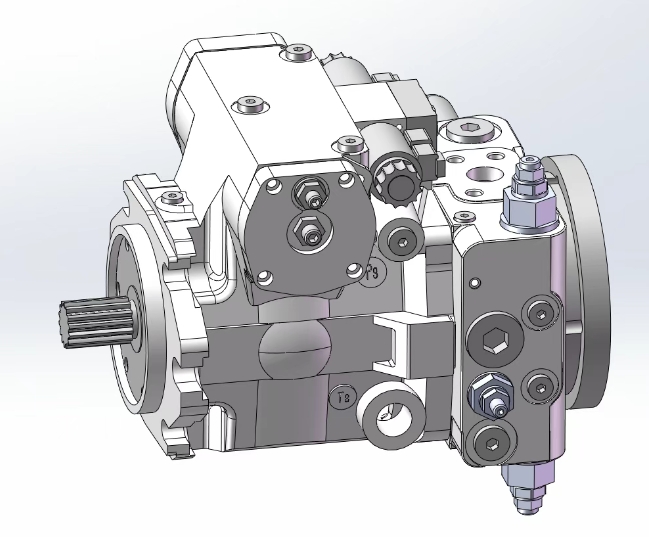

Унутры восевага поршневага помпы: ключавыя часткі

Давайце разбіваем асноўныя кампаненты, якія прымушаюць гэтыя помпы працаваць:

1. Блок цыліндру

Гэта як галоўнае цела, якое трымае ўсё разам. Ён круціцца вакол і мае дзіркі для поршняў.

2. Портаны

Гэта невялікія цыліндры, якія рухаюцца туды -сюды. У большасці помпаў ёсць 7 ці 9 поршняў (заўсёды няцотны лік, каб зрабіць паток больш гладкім).

3

Гэтая кутняя пласціна-гэта разумная частка, якая ператварае руху, які рухаецца ў руху поршня. Падумайце пра гэта як кулачок у машыне.

4. Вал прывада

Гэта злучаецца з рухавіком і робіць усё круціцца.

5. Пласцінка клапана

Гэта кантралюе там, дзе вадкасць ідзе і выходзіць, як святлафоры для гідраўлічнай вадкасці.

Як адбываецца магія: працэс прапампоўкі

Працэс дзіўна просты:

Крок 1: Фаза ўсмоктвання

- Поршні цягнуць назад, ствараючы пустую прастору

- Гідраўлічная вадкасць высмоктваецца праз уваход

- Гэта як выкарыстанне шпрыца для стварэння лекаў

Крок 2: Фаза разраду

- Поршні штурхаюцца наперад, выціскаючы вадкасць

- Праз выхад вадкасці праходзіць праз разетку

- Гэта стварае паток, які можа ўзмацніць ціск

Гэта адбываецца тысячы разоў у хвіліну, ствараючы ўстойлівы паток вадкасці высокага ціску.

Два тыпы: Выпраўленае супраць пераменнага перамяшчэння

Восевыя поршневыя помпы бываюць у двух асноўных водарах:

- Кут перакрыцця ніколі не мяняецца

- Яны заўсёды прапампоўваюць аднолькавую колькасць вадкасці

- Просты і надзейны, як асноўны аўтамабільны рухавік

- Кут перакрыцця можа быць адрэгуляваны

- Вы можаце кантраляваць, колькі вадкасці яны прапампоўваюць

- Больш складаны, але значна больш гнуткі

- Як наяўнасць машыны з пастаянна зменнай перадачай

У рэальным свеце прыкладанні: дзе вы знойдзеце гэтыя помпы

Восевыя поршневыя помпы ёсць усюды, нават калі вы іх не бачыце:

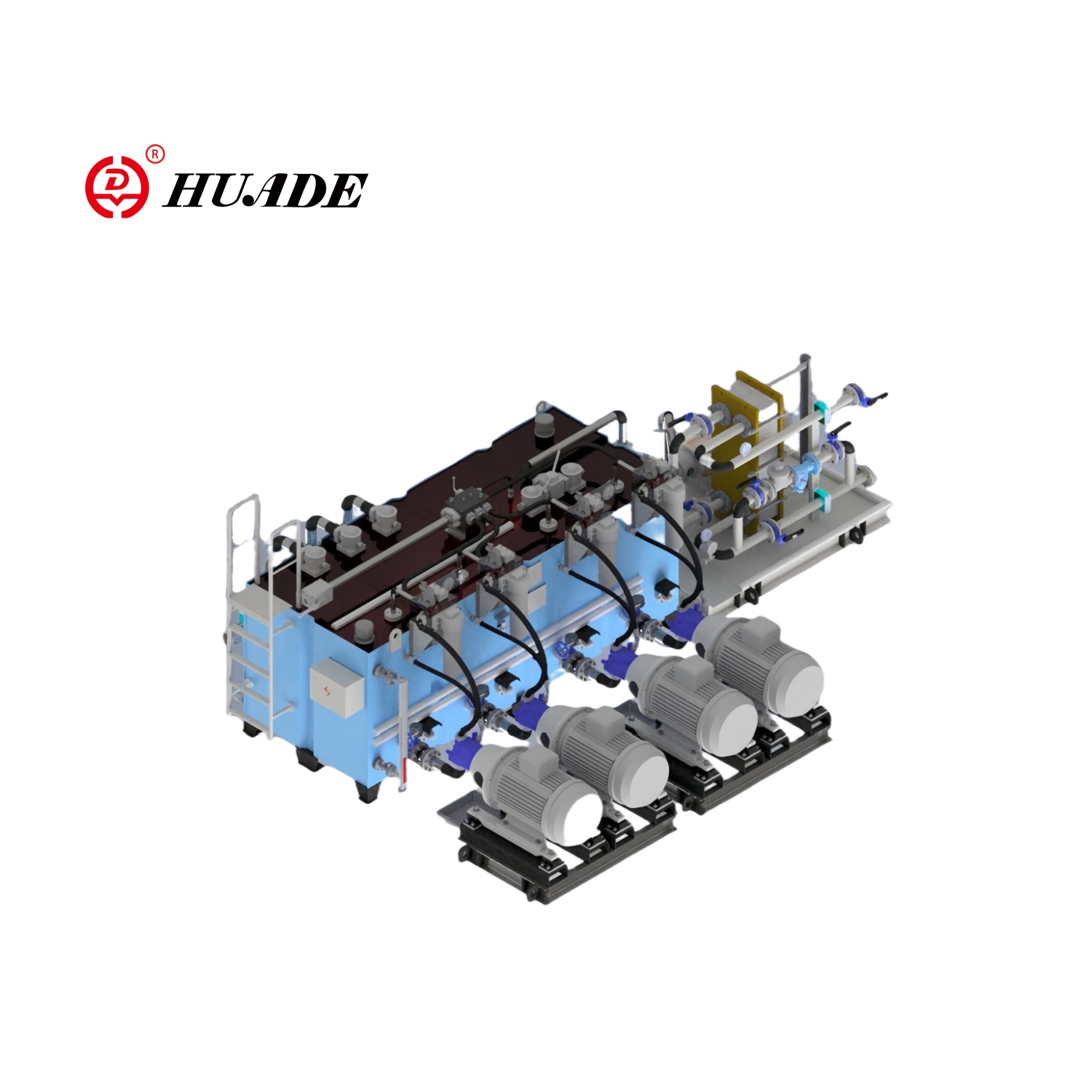

Будаўнічае абсталяванне

- Экскаватары выкарыстоўваюць іх для ўзняцця тон бруду

- Бульдозеры прасоўваюць жорсткую мясцовасць

- Краўны падымаюць цяжкія матэрыялы на вялікія вышыні

Прамысловыя машыны

- Гідраўлічныя прэсы ў форме металічных дэталяў

- Машыны з ЧПУ выразаюцца з неверагоднай дакладнасцю

- Машыны для ліцця пад ціскам робяць пластыкавыя прадукты

Перавозка

- Самалёт выкарыстоўваюць іх для пасадкі і кіравання палётам

- Караблі разлічваюць на іх для рулявога

- Нават некаторыя сістэмы кандыцыянавання аўтамабіляў выкарыстоўваюць іх

Сельская гаспадарка

- Трактары выкарыстоўваюць гідраўлічную магутнасць для ўкладанняў

- Наборшчыкі працуюць з складанымі механізмамі рэзкі

- Сістэмы арашэння эфектыўна перамяшчаюць ваду

Магчымасці ціску: наколькі яны моцныя?

Розныя восевыя поршневыя помпы могуць апрацоўваць розныя ўзроўні ціску:

- Мадэлі сярэдняга ціску:Да 3600 фунтаў на кв.дюйм

- Мадэлі высокага ціску:5000 да 6500 фунтаў на кв.дюйм

- Спецыялізаваныя помпы:Некаторыя могуць пайсці яшчэ вышэй

Каб паставіць гэта ў перспектыве, тыповая аўтамабільная шына мае каля 30-35 фунтаў на квадратны квадрат. Гэтыя помпы могуць стварыць ціск, які ў 100-200 разоў мацней!

Чаму ціск мае значэнне

Ціск - гэта тое, што надае гідраўлічнай сістэмы сваю неверагодную сілу. Вось чаму:

Сіла множання

Выкарыстоўваючы прынцып Паскаля (названы ў гонар разумнага французскага хлопца), гідраўлічныя сістэмы могуць памнажаць сілу. Невялікая сіла на невялікай поршня можа стварыць велізарную сілу на вялікім поршне.

Дакладны кантроль

Высокае ціск дазваляе забяспечваць вельмі дакладныя руху, таму ў кіраванні самалётамі і хірургічнага абсталявання выкарыстоўваюцца гідраўлічныя сістэмы.

Кампактная магутнасць

Гідраўлічныя сістэмы могуць забяспечваць велізарную магутнасць з адносна невялікіх кампанентаў, што робіць іх ідэальнымі для мабільнага абсталявання.

Агульныя праблемы і рашэнні

Як і любая машына, восевыя поршневыя помпы могуць мець праблемы:

Ціск пульсацыя

Праблема:Паток не зусім роўны, ствараючы вібрацыі

Рашэнне:Выкарыстоўвайце няцотную колькасць поршняў і спецыяльных канструкцый клапана

Унутраная ўцечка

Праблема:Вадкасць уцечка ўнутры помпы, зніжаючы эфектыўнасць

Рашэнне:Рэгулярнае абслугоўванне і якасць гідраўлічнай вадкасці

Перагрэў

Праблема:Высокі ціск стварае цяпло, што можа пашкодзіць пячаткі

Рашэнне:Правільныя сістэмы астуджэння і клапаны для зняцця ціску

Парады па тэхнічным абслугоўванні: захаванне помпы шчаслівым

Каб захаваць восевы поршневы помпа працаваць добра:

- Трымайце вадкасць у чысціні- Бруднае алей - вораг гідраўлічных сістэм

- Рэгулярна мяняйце фільтры- Падумайце пра іх як пра паветраныя фільтры помпа

- Сачыце за ціскам і тэмпературай- Занадта шмат любога можа выклікаць праблемы

- Праверце ўцечкі- Знешнія ўцечкі адходу адходу; Унутраныя ўцечкі зніжаюць эфектыўнасць

- Выконвайце графікі тэхнічнага абслугоўвання- Рэгулярныя агляды прадухіляюць вялікія праблемы

Параўнанне восевых поршневых помпаў з іншымі тыпамі

Перадачы перадач:Прасцей, танней, але абмежаванага ціску

Восевы поршань:Больш складаны, дарагі, але значна большая здольнасць да ціску

Помпавыя помпы:Цішэйшы, больш гладкі паток, але не такі моцны

Восевы поршань:Гучней, але можа справіцца з надзвычайным ціскам

Цэнтрабежны:Выдатна падыходзіць для перамяшчэння вялікай колькасці вады пры нізкім ціску

Восевы поршань:Ідэальна падыходзіць для высокага ціску, дакладных прыкладанняў

Будучыня восевых поршневых помпаў

Тэхналогія працягвае ўдасканальваць гэтыя помпы:

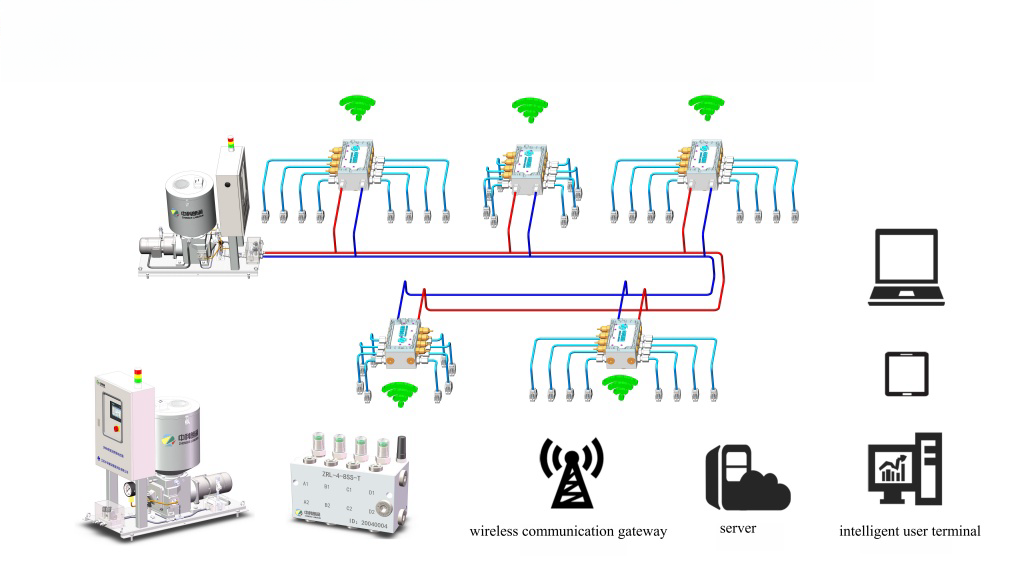

Разумныя элементы кіравання

Новыя помпы могуць аўтаматычна рэгуляваць свой выхад у залежнасці ад таго, што патрэбна сістэме, эканоміць энергію і павышаючы прадукцыйнасць.

Лепшыя матэрыялы

Пашыраны матэрыялы прымушаюць помпы доўжыцца даўжэй і апрацоўваюць больш высокі ціск.

Лічбавы маніторынг

Датчыкі могуць прадказаць, калі неабходна абслугоўванне, прадухіляючы нечаканыя паломкі.

Энергаэфектыўнасць: чаму гэта важна

Сучасныя восевыя поршневыя помпы неверагодна эфектыўныя:

- Аб'ёмная эфектыўнасць:Да 96% вадкасці фактычна выпампоўваецца

- Механічная эфектыўнасць:Вельмі мала энергіі марна, як цяпло

- Пераменнае зрушэнне:Толькі прапампоўвае тое, што трэба, эканоміць энергію

Гэтая эфектыўнасць важная, таму што:

- Гэта эканоміць грошы на электраэнергіі

- Гэта памяншае выпрацоўку цяпла

- Лепш для навакольнага асяроддзя

Выбар правільнага помпа

Пры выбары восевага поршневага помпы ўлічыце:

Патрабаванні да ціску

Колькі ціску на самай справе патрэбна вашай сістэме? Не негабарыце - гэта марнуе энергію і грошы.

Расход

Колькі вадкасці трэба рухацца ў хвіліну? Гэта вызначае памер помпы.

Тып кіравання

Ці патрэбны вам фіксаваны выхад або зменнае кіраванне? Пераменная каштуе даражэй, але прапануе гнуткасць.

Навакольнае асяроддзе

Ці будзе гэта працаваць у памяшканні ці на свежым паветры? У чыстых ці брудных умовах? Тэмпературныя крайнасці?

Бюджэт

Баланс авансавых выдаткаў з доўгатэрміновымі эксплуатацыйнымі выдаткамі і надзейнасцю.

Меркаванні бяспекі

- НіколіПраца над сістэмамі пад ціскам

- Заўсёды выкарыстоўвайце належнае абсталяванне для бяспекі

- Прайсці навучанне перад працай гідраўлічнай тэхнікі

- Паважайце магутнасць - гідраўлічная вадкасць пад ціскам можа прарэзаць скуру

Разуменне сістэмнай інтэграцыі

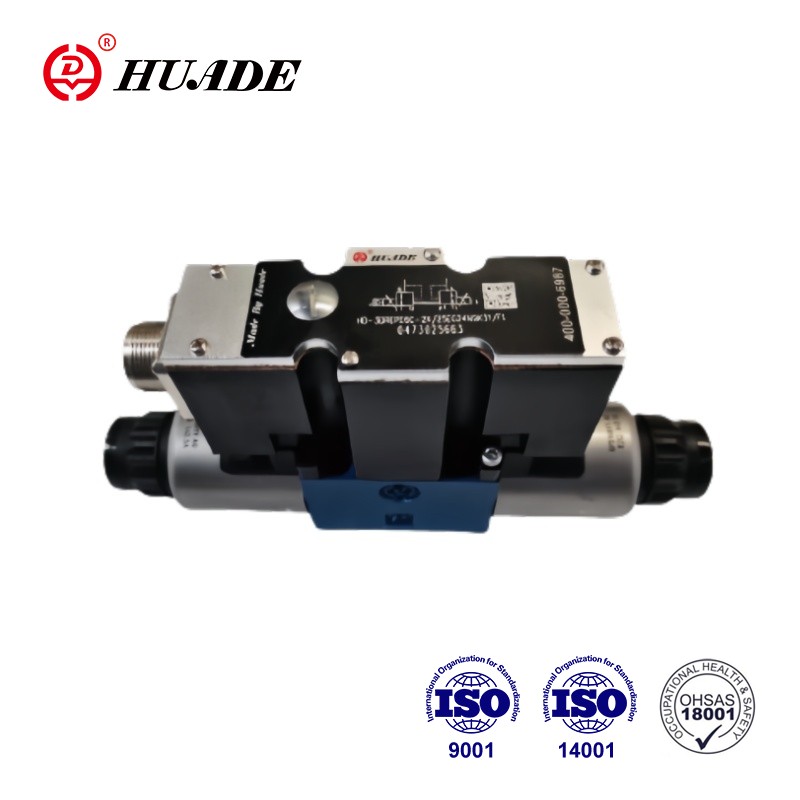

Восевыя поршневыя помпы не працуюць у адзіноце. Яны ўваходзяць у поўную гідраўлічную сістэму, якая ўключае:

Вадасховішча

Захоўвае гідраўлічную вадкасць і дазваляе ёй астываць

Фільтры

Трымайце вадкасць у чысціні і абараняйце кампаненты сістэмы

Клапаны

Кіруючы кірунак патоку, ціск і хуткасць

Прывады

Пераўтварыць гідраўлічную магутнасць назад у механічныя працы (цыліндры, рухавікі)

Сістэма астуджэння

Кіруе цяплом, якое ўтвараецца ў сістэме

Ліквідацыя агульных праблем

Выхад нізкага ціску

- Праверце ўнутраную ўцечку

- Праверце налады перамяшчэння помпы

- Шукайце знешнія ўцечкі

- Праверце наладу клапана дапамогі

Празмерны шум

- Праверце ўзровень і якасць вадкасці

- Шукайце паветра ў сістэме

- Праверце належнае мантаж

- Праверце зношаныя кампаненты

Перагрэў

- Праверце сістэму астуджэння

- Праверце належную глейкасць вадкасці

- Шукайце празмерны ціск

- Праверце заблакаваныя фільтры

Сутнасць

Такім чынам, ці ствараюць восевыя поршневыя помпы? Абсалютна! У той час як яны ў першую чаргу ствараюць паток, гэты паток становіцца ціскам, калі ён адпавядае супраціву ў гідраўлічнай сістэме. Гэты ціск - гэта тое, што надае гідраўлічнаму абсталяванню неверагодную сілу і дакладнасць.

Гэтыя помпы - гэта інжынерныя цуды, якія зрабілі рэвалюцыю ў незлічоных галінах. Ад экскаватара, які бяспечна капае ваш падмурак да пасадкі самалётаў у аэрапорце, восевыя поршневыя помпы працуюць за кулісамі, каб зрабіць наш сучасны свет магчымым.

Разуменне таго, як яны працуюць, дапамагае нам ацаніць неверагодную тэхніку, якая ідзе ў паўсядзённыя машыны. У наступны раз, калі вы ўбачыце кавалак цяжкага абсталявання, вы даведаецеся, што ўнутры ёсць восевы поршневы помпа, ціха ствараючы ціск, неабходны для перамяшчэння гор - літаральна!

Ключавыя выезды

- Восевыя поршневыя помпы ствараюць паток, які становіцца ціскам, калі ён адпавядае супраціву

- Яны могуць справіцца з надзвычай высокім ціскам (да 6500+ фунтаў на кв.дюйм)

- Яны выкарыстоўваюцца ў будаўніцтве, аэракасмічнай, прамысловай і сельскагаспадарчай абсталяванні

- Правільнае абслугоўванне мае вырашальнае значэнне для доўгага жыцця і надзейнай працы

- Пераменныя помпы зрушэння прапануюць больш высокую энергаэфектыўнасць і кантроль

- Яны больш складаныя, чым іншыя тыпы помпаў, але прапануюць цудоўныя характарыстыкі для прыкладанняў высокага ціску

Незалежна ад таго, што вы студэнт вывучаеце гідраўліку, тэхнік, які падтрымлівае абсталяванне, ці проста хтосьці цікавы, як працуюць магутныя машыны, разуменне восевых поршневых помпаў адкрывае займальны свет тэхнікі і тэхналогій.